10 best practices for ESU performance testing

1. Always refer to the manufacturer’s service manual

Manufacturer recommended test procedures should always be followed. Refer to the service manual for performance inspection tasks specific to the device. These service manuals typically recommend an inspection frequency. Complete the performance inspection per manufacturer’s procedure.

2. Adopt a consistent inspection frequency

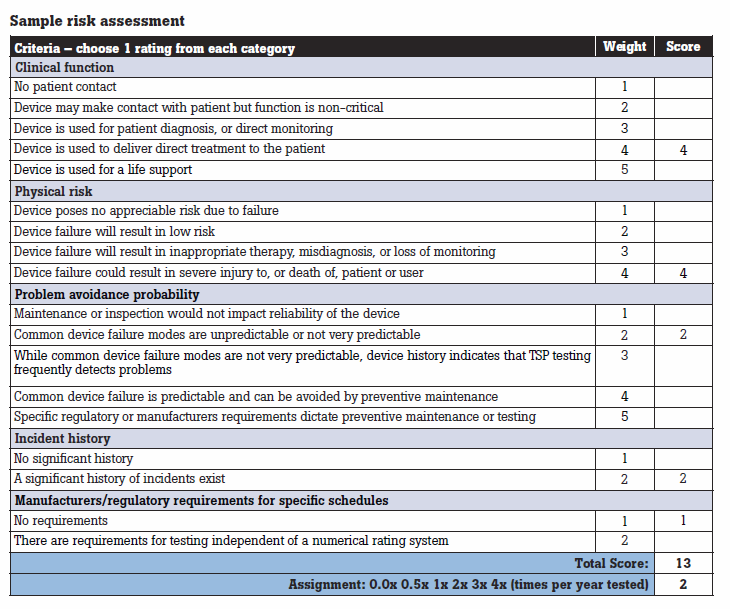

If the service manual and inspection procedure from the manufacturer is not available, the frequency of inspection must still be determined. One method for determining how often a medical device should be tested is a risk-based method used by the University of VT Biomedical Engineering Department. As shown in the table below, this method is described in Medical Equipment Quality Assurance: Inspection Program Development and Procedures by J. Tobey Clark. This method recommends a bi-annual (every six months) test frequency for electrosurgical devices. Additionally, most major electrosurgical device manufacturers recommend semi-annual preventive maintenance testing to ensure the performance of the unit.

3. Adopt a formal standardized test procedure

If the service manual and inspection procedure from the manufacturer is not available, it is still the responsibility of the medical facility to choose and standardize on a test procedure. It is important that the electrosurgery generator functionality be quantitatively evaluated by comparing it to the manufacturer’s specifications, or the requirements in the applicable medical device standard. When the medical device manufacturer’s specifications are not known, the IEC standard requirements are a reasonable substitute. Once the inspection criteria have been agreed, no changes should be made without a rationale statement describing why a change was required, what the change is, and how this change was validated.

4. Pair additional test equipment with your electrosurgical analyzer for comprehensive testing

Most manufacturer performance inspection procedures require electrical safety tests including ground wire resistance and chassis leakage. Keep an electrical safety analyzer close by to complete the electrical safety portion of the performance inspection easily.

Additionally, a medical oscilloscope can be used to show the actual wave shape of the device under test (DUT). This waveform output can be compared to the DUT’s service manual.

Please see two possible solutions below.

5. Be mindful of test leads while testing

Keep all test leads and interconnecting leads as short as possible and do not cross or coil measurement leads. Radio frequency energy behaves differently than low-frequency energy. It radiates and induces electrical current flow in addition to any conductive current flow through test leads that cross and coiled leads. When leads are too long, they act more like an antenna than test leads.

6. Always exercise caution when dealing with active electrodes

Active electrodes present many dangers. Do not touch the active electrode or return pad/plate of the ESU while it is activated in either cut or coagulation mode. Turn off the ESU before adjusting or removing connections.

Additionally, be aware of other flammable hazards including alcohol, oxygen and moisture.

7. Perform all tests necessary to ensure performance

Power distribution/output tests: Power distribution/output tests measure the power output properties of the ESU and supply output current (A), power (W), peak-to-peak voltage (V), and crest factor values. The power distribution test evaluates the output across multiple loads to determine how well the impedance-sensing circuits of new generation electrosurgery generators automatically adjust the output of the ESU so that it is not reduced by the presented load.

High Frequency (RF) leakage current tests: The RF leakage current in electrosurgical units is a critical parameter to measure because it may cause accidental burns in patients. The particular standard for electrosurgical units, IEC 60601-2-2, indicates the maximum RF leakage levels and defines the elements and their layout to do these measurements.

RECM tests: The RECM (return electrode current monitor) is the “watch-dog” that alarms (both audibly and visually) and prevents the electrosurgery generator from energizing when the high limit threshold for current flowing through the return electrode plate or pad has been exceeded.

Inert gas flow and pressure parameters: In some electrosurgery generators a special option allows an inert gas envelope to be produced encasing the surgery site so that oxygen is eliminated at that specific spot. Oxygen causes charring of the tissue at the site of the surgery. Eliminating oxygen prevents this charring and produces cleaner, more precise incisions. These more precise wounds heal faster, with less opportunity for infection of the tissue. Test the gas flow and pressure for such inert gas outputs.

8. Use test automation to quickly perform tests, document measurements, and archive data

One of the best ways to shorten learning curves for infrequently used test instruments and new or infrequently scheduled testing is to standardize the procedure.

Test standardization helps ensure all testing is completed in a consistent sequence, recorded and archived accurately, and meets regulatory requirements.

Test automation can also drastically reduce test time. According to Medical Equipment Quality Assurance: Inspection Program Development and Procedures by J. Tobey Clark, the average test time for most electrosurgical unit tests is 35 minutes. When coupled with the QA-ES III Electrosurgery Analyzer, Ansur Test Automation Software can reduce average test time to under 15 minutes.

Other benefits of using test automation to test electrosurgical units include easy data traceability, simplified data extraction for reporting, and reduced human error.

9. Document electronically and always archive test results

It is critical that the data gathered is recorded accurately. Data can be recorded manually or electronically. Manual recording could mean documenting on paper or typing into an electronic source such as a PC. Some issues associated with documenting manually include misplaced records, legibility, skipped tests, and recording errors. This method is time-consuming as well. To ensure data integrity, record electronically. Consider an analyzer that has the ability to store data. The purpose of testing and producing test results is to have a continuing stream of data showing all changes in the performance and safety of the electrosurgery generator year over year.

Long-term trending of this statistically relevant information provides the basis for predictive maintenance (i.e., when the next repair is most likely to happen) so that parts (especially long-lead time and costly parts) can be ordered and received just-in-time for the repair event. This saves money and increases the amount of time the medical device is available for use.

The best place to archive test result information is in a database/CMMS (computerized maintenance management system). Archiving paper into filing cabinets rarely results in anyone capturing or understanding the long-term implications of failures.

10. Choose to test with an analyzer that you can depend on for complete preventive maintenance and safety testing

Use the following criteria when selecting an analyzer for electrosurgical device testing:

• Can it test all ESU parameters required by the manufacturer?

• Is it easy to use (and learn)?

• Does it have the ability to store data for easy retrieval/reporting?

• Can it be automated?

• Is it easy to transport?

• What is the return-on-investment?