Interpreting and adjusting the graphical output of the VT650 and VT900A

By Steven Parsons

Testing a ventilator always starts with traceable measurement standards, such as gas flow and pressure, but ventilators have more parameters than flow and pressure. To test a ventilator thoroughly, a gas flow analyzer needs to examine the flow and pressure over time to measure a variety of “breath parameters” including breath rate, peak inspiratory flow, expiratory tidal volume, positive end expiratory pressure, and many others. These parameters are based on standard measurements involving time, flow and pressure, but they have more distinction to them and aren’t directly traceable to a national metrology standard.

Testing a ventilator always starts with traceable measurement standards, such as gas flow and pressure, but ventilators have more parameters than flow and pressure. To test a ventilator thoroughly, a gas flow analyzer needs to examine the flow and pressure over time to measure a variety of “breath parameters” including breath rate, peak inspiratory flow, expiratory tidal volume, positive end expiratory pressure, and many others. These parameters are based on standard measurements involving time, flow and pressure, but they have more distinction to them and aren’t directly traceable to a national metrology standard.

VT900A and VT650 Gas Flow Analyzers from Fluke Biomedical introduce a new feature to ensure the analyzer is set up correctly to measure the ventilator breath parameters. These new gas flow analyzers show a visualization of the ventilator state in real-time on the flow and pressure graphs.

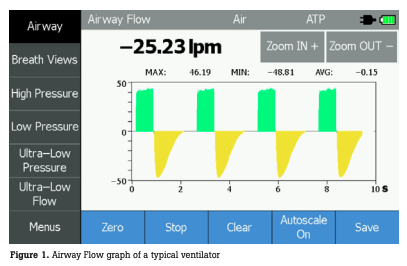

Initially, users may look at the flow graph and see the colors show positive flow in green and negative flow in yellow. It’s quite helpful to have color to distinguish the positive from negative flow, but there is more information conveyed in the color for a careful observer.

Both flow triggering and pressure triggering on the analyzer give thresholds where the state of the breath changes from inhale, to exhale, and back again. This triggering is based on the measured flow or pressure and is independent of the ventilator. There is no way for the analyzer to know for certain whether it is “right” or “wrong”. It is up to the user to correctly set the thresholds to ensure the breath parameters are measured correctly. An incorrect setting may result in an additional error for the measurement or may even result in measurements which make no sense at all.

Often, when the user sets the thresholds, they may rely on a service manual, past experience, or guessing, to adjust the thresholds until they read close to what the ventilator measures. The colored graphs on VT900A and VT650 allow the user to have more understanding of how the thresholds affect the breath detection and thus the measurement of breath parameters.

The colors can be summarized as:

- Green: The analyzer detected the ventilator is breathing into the test lung (inhalation)

- Yellow: The analyzer detected the ventilator is allowing the test lung to exhale

- Gray: The analyzer detected neither an inhale or exhale state. It is waiting for either an inhale or exhale to occur. This is later referred to as the intermediate state.

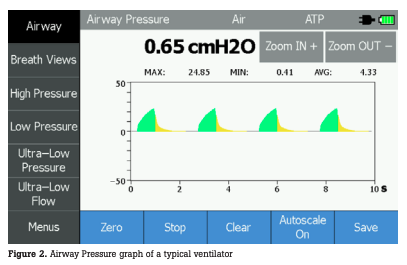

Many ventilators work well with the default threshold settings of 2 liters per minute for both inspiratory and expiratory triggers. For instance, default settings on a typical ventilator may look like Figures 1 and 2, above, with the default threshold settings.

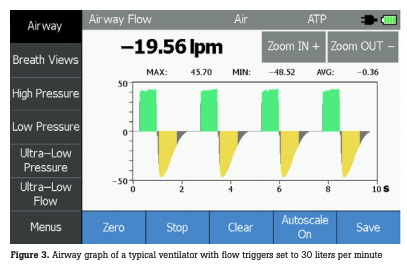

Often, increasing the threshold has minimal impact on the breath parameter measurements, but a higher threshold will make the graphs appear different. Until the flow or pressure reaches the set threshold, the analyzer remains in the gray intermediate state. As a result, a higher threshold will have more of the graph colored gray (see Figure 3, above). It is worth noting that the gray color does not mean information is being lost, but only the threshold for detecting a true inhalation or exhalation is different. Volume, time and pressure are still recorded in the intermediate state and assigned to the correct breath period (inhale or exhale) as the threshold is passed.

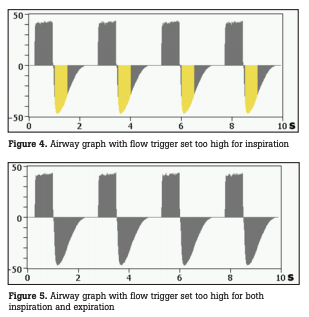

If a threshold is increased too much, the analyzer will not be able to correctly trigger. This may be shown as a color missing in bidirectional triggering mode (see Figure 4, below), which indicates one of the thresholds is too high, or as the graph always being gray (see Figure 5, below), which indicates both thresholds are too high.

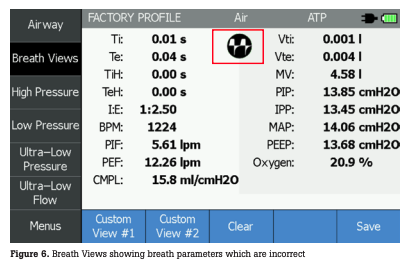

One of the most useful benefits from the colored graphs is to show the user a problem with a noisy signal. For instance, a portable ventilator with a pneumatically controlled exhalation valve may add significant noise on the flow measurement when a high PEEP setting is used as it pulses the exhalation valve to maintain the required pressure. If the trigger setting is too low, measurement problems will be evident in the breath parameters where many readings are incorrect (see Figure 6, below). Additionally, a trigger set too low with noisy flow data will also have the trigger icon light up green more than once per breath.

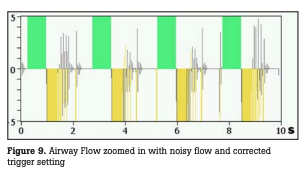

The colored graphs show exactly what is happening to cause measurement problems with a low trigger setting combined with noisy flow. When looking at the flow graph, some noise may be initially apparent, but details of the colors in the noise may be hard to see (Figure 7, below). Pressing the Zoom IN + button to change the vertical scale until the noise fills the screen will help make the problem easier to see (Figure 8, below). After zooming in, the problem becomes clearer – the noise in the flow on exhale is causing the analyzer

to interpret the noise as additional breaths. This can be seen by the color changing from yellow to green and back to yellow during the exhale period of the breath.

Using the information shown in Figure 8, the user can correct the problem by increasing the trigger settings beyond the worst peaks in the positive and negative flow. In this example, setting both triggers to 10 liters per minute is beyond the noise, but still below the maximum inspiratory and expiratory flows. The new trigger setting allows the analyzer to ignore the noise while still capturing both the inhale and exhale correctly.

Once the correct trigger settings are determined for a given ventilator to meet its test requirements, it is advisable to save those settings into the analyzer as a profile specific to that ventilator for later use.